Integrated Engines for all Platforms

Why Work With us

Made in the Netherlands

Rotaero Wankel engines are proudly made in the Netherlands, combining Dutch engineering excellence with a commitment to precision, reliability, and cutting-edge innovation. Manufactured to exacting standards, these engines deliver exceptional performance while remaining ITAR-free, ensuring unrestricted global use and supporting truly independent, advanced propulsion solutions

Patented Technology

The new inlet concept has perspectives for use with different fuels, such as Jet fuels and hydrogen. With an additional inlet air cooler the engine’s continuous power can be increased to 90-95% of peak power, and it has run successfully on Jet A-1 fuel.The porting system is also suitable for charging, especially when applying a novel charging concept (patent granted in Germany, China, India) USA is pending, which can further increase peak and continuous power to >40kW and also act as an altitude compensation.

Built for Manned and Un-manned Aircraft

Rotaero designs and manufactures two versions of its advanced rotary engines—a single-rotor and a twin-rotor model—tailored for both manned and unmanned aircraft applications. The single-rotor engine delivers lightweight, compact power ideal for UAVs and light sport aircraft, while the twin-rotor variant provides higher output and smoother operation for larger platforms requiring greater range and payload capacity. Both engines emphasize reliability, fuel efficiency, and ease of integration to meet the demanding needs of modern aviation.

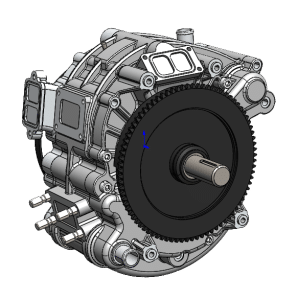

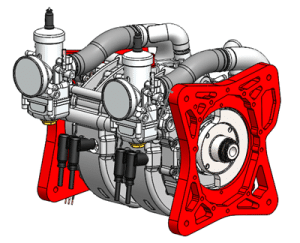

Availble in Two Engine Size

Rotaero offers two advanced 4-stroke Wankel rotary engines for aviation: the S3, a single-rotor 294 cm³ unit delivering 30 kW and 35 Nm torque—ideal for lightweight, fuel-efficient applications (5–8 l/h typical consumption); and the D3, a twin-rotor 2×294 cm³ model producing 54 kW and over 70 Nm torque, suited for higher-power demands with typical consumption of 10–16 l/h. Both engines feature CDI-Magneto or battery ignition, integrated generators, and compatibility with MoGas or AvGas.

Maximum Flexibility

Both the S3 and D3 rotary engines are available in a wide range of configurations to ensure maximum flexibility and easy integration. Options include multiple mounting arrangements, starter types, generator outputs, carburetor variants, and advanced electronic fuel injection (EFI) systems. This modular approach allows Rotaero engines to be tailored precisely to diverse aircraft requirements, supporting both manned and unmanned platforms.

Low Vibration

Wankel engines are known for low vibration because they use a rotary design with smooth, continuous rotational motion rather than the reciprocating (back-and-forth) motion of pistons. This eliminates the abrupt acceleration and deceleration forces typical in conventional engines, resulting in fewer unbalanced forces and inherently smoother operation with less vibration.